Micromachined Silicon Diffractive Optics

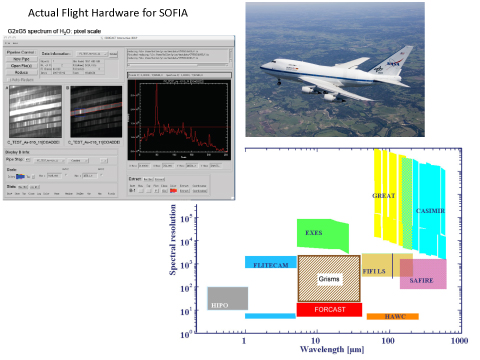

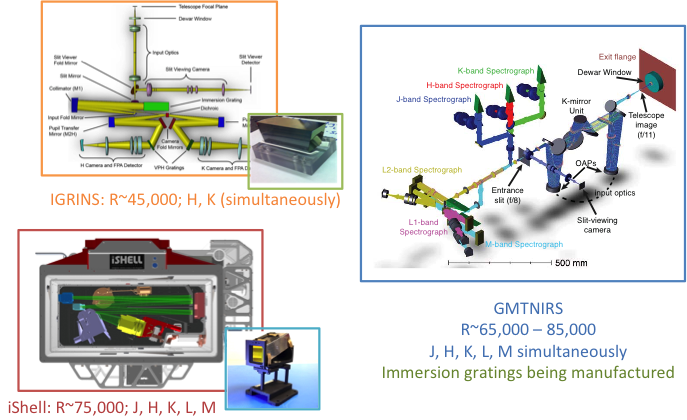

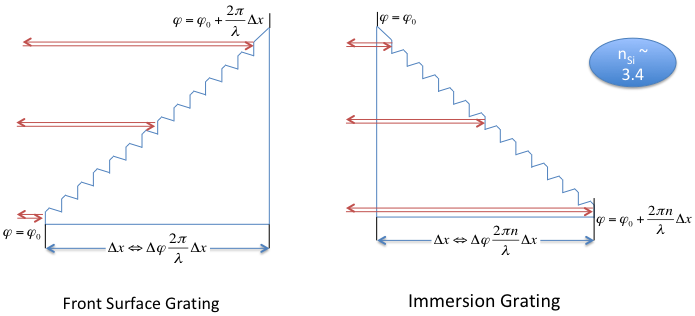

The silicon diffractive optics group manufactures diffraction gratings in silicon. These gratings can be either reflective gratings used in immersion (immersion gratings) or transmissive grating prisms (grisms). Our immersion gratings are found in the IGRINS and iShell instruments, and we are currently manufacturing immersion gratings for GMTNIRS. We have manufactured silicon grisms for the FORCAST camera on NASA’s SOFIA Airborne Observatory and the NIRCAM instrument on JWST.

These devices offer substantial advantages in compactness, formatting, and efficiency over other dispersive devices. For example, high-resolution spectrographs designed around immersion gratings can have volumes an order of magnitude smaller than comparable instruments built around conventional gratings. In addition, the ability to make coarse grooves using micromachining allows us to produce gratings that make it possible for the first time for infrared instruments to have continuous wavelength coverage over large bands at high resolution.

Figure 1. Spectrographs with silicon immersion gratings built by our group.

Figure 2. We have fabricated grisms for FORCAST that give it a spectroscopic capability in the 5-30 micron range.

Figure 3. We produced a set of 4 grisms incorporated into the long wavelength arm of NIRCAM giving it an R=1800 capability for slitless spectroscopy.

Silicon immersion gratings

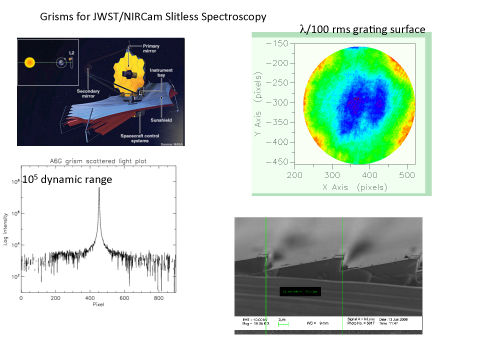

Immersion gratings are reflective optics used as dispersive elements in high-resolution spectrographs. In an immersion grating, the light is incident on the grating surface from the inside, where the wavelength is shortened by a factor equal to the refractive index (3.4 for Si). This allows a grating of a given size to have 3.4 times the resolving power of a conventional front-surface device.

Figure 4. Illustration of light path for a front surface grating (left) and an immersion grating (right).

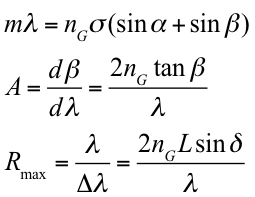

There are great spectroscopic advantages to using silicon for immersion gratings. If we look at the grating equation in immersion, the internal wavelength shrinks by a factor of the index of refraction (nG = 3.4) and the angular dispersion increases by a factor of nG. For a grating of length L and blaze angle δ and operating wavelength λ, the limiting resolving power also increases by a factor of nG. The angular dispersion, A, and the maximum resolving power, Rmax, are given in the Littrow configuration in which α = β = δ:

We are currently manufacturing five gratings to be used in the GMTNIRS spectrograph. The GMTNIRS instrument uses a 90mm long R3 (blazed at 71.56°) immersion gratings for the J, H, and K channels, and 125 mm long R4 (blazed at 75.96°) for the L1, L2, and M channels.

Figure 5. Some of the immersion gratings surfaces manufactured for the GMTNIRS instrument. The smaller gratings will be used in the J, H, and K channels (1.1 – 2.5 μm) and the larger gratings will be used in the L1, L2, and M channels (2.9 – 5.3 μm). We are looking at the blazed grating surface rotated to the Littrow configuration, at which the angle that light incident on the grating is reflected back in the direction from which it came.

Silicon grisms

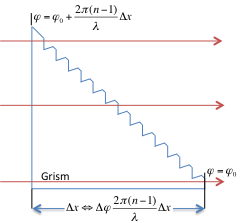

Grisms are dispersive transmission optics that are often used in instruments that combine imaging and spectroscopy. The resolving power of devices with the same opening angle depends on the refractive index of the substrate as (n-1). Silicon grisms of a given size have resolving powers 3-4 times greater than those of grisms made from glass or other low index materials

Figure 6. A grism is a transmission grating mounted or etched into a prism-shaped dielectric substrate. The light enters on the left and is diffracted by the grating as it exits.

Why do we use silicon?

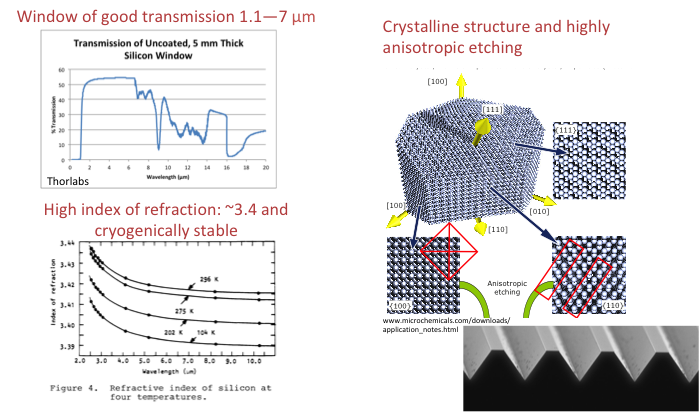

Silicon is particularly useful for immersion gratings and grisms for spectrographs operating in the near infrared (NIR). Silicon has a high index of refraction (3.4) and excellent transmission in the range of 1.1 – 7 μm. It is stable at the cryogenic temperatures necessary to operate in the infrared. Finally, silicon can be processed with well-known techniques originally devised for the semiconductor industry. Because silicon has a crystalline structure with high anisotropic etch ratio (in other words, it etches in one direction much faster than it etches in another), very smooth, near-perfect grooves can be micro-machined into the surface.

Figure 7. Properties of silicon that make it an excellent choice for immersion gratings to be used in the near infrared.

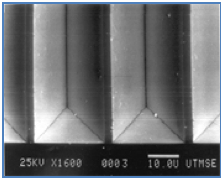

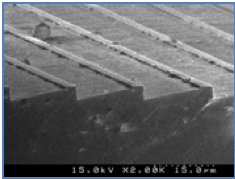

Figure 8. (left) Scanning electron micrograph of grooves etched into a silicon wafer. The opening angle for such grooves is 70°, rather than the 90° angle produced by conventional ruling. The groove surfaces are much flatter than in ruled gratings. (right) In grisms and in many immersion gratings, the grooves must be etched at an angle with respect to the silicon crystal planes. Here we show a test that produced grooves at a very steep bias angle.

Manufacturing Techniques

We use the same silicon fabrication techniques used in nanotechnology to produce the grooves in our diffractive optics. We pattern the grooves onto silicon using photolithography and then etch away part of the crystal to form V-shaped grooves. The feature size of our grooves is large (typically 20-150 μm), but the groove positions must come at regular intervals with a precision of only 20-30 nm over the entire size of the piece.

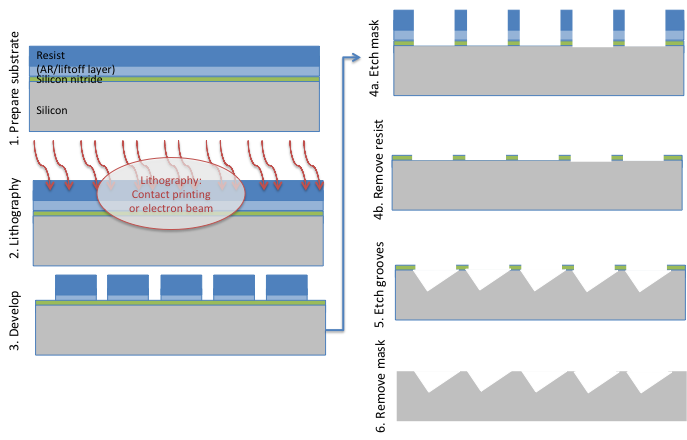

Pre-fabrication steps include x-ray crystallographic alignment of very high-purity silicon and precision machining the orientation of the silicon crystal to 0.05°. The silicon disks are chemically-mechanically polished (CMP) and a layer of silicon nitride is deposited though low-pressure chemical vapor deposition (LPCVD). The substrate is then spun at high-speed and a photosensitive material (photoresist) is applied. Contact lithography or direct electron beam writing is used to expose lines in the photoresist and the exposed area is washed away in a chemical solution. The photoresist is used as a mask to plasma etch the silicon nitride lines and the photoresist is then removed. The silicon nitride lines for a mask for the potassium hydroxide chemical bath used to etch v-shaped grooves into the silicon. Finally, the silicon nitride mask is removed in a hot phosphoric acid bath.

Figure 9. Processing steps used to manufacture silicon immersion gratings.

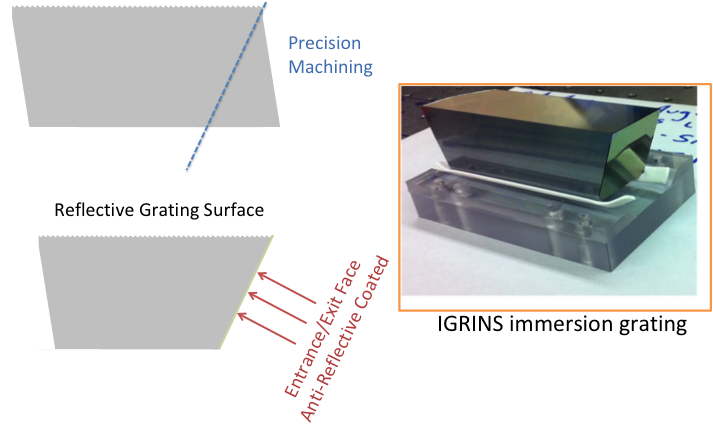

Figure 10. To form the silicon immersion grating, the substrate is precision machined. The face that the light will be incident on (entrance face) is polished and an anti-reflective coating is applied. Finally, a reflective coating is applied to the groove surface.

Characterization of the gratings

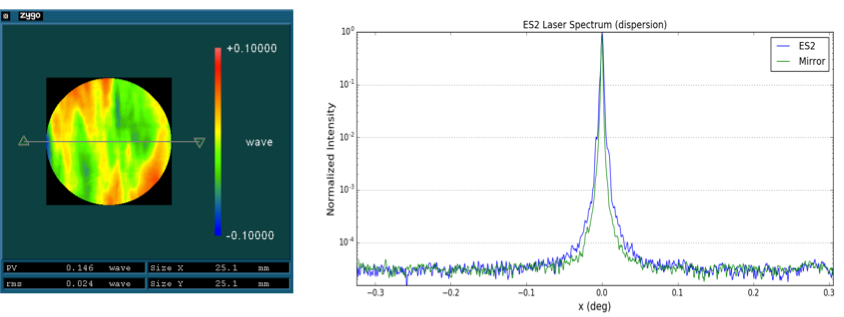

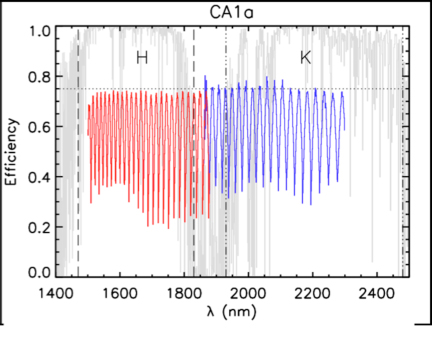

We perform testing to understand the characteristics of the gratings we manufacture. First, we visually inspect the grating for defects. We conduct optical tests including an interferogram measured on the front surface in reflection. We rotate the grating such that it is measured in Littrow with the blazed surface illuminated. The phase errors in the direction of propagation are a measurement of groove spacing errors. We take a monochromatic spectrum either on the front surface or in immersion to understand the point spread function and compare this to a mirror in the same setup. After the grating has been shaped and coated, we measure the efficiency of the grating over the operation wavelength band.

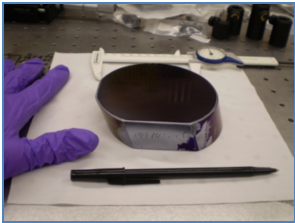

Figure 11. (left) Machined grating surface for the IGRINS immersion echelle etch into a 30mm thick, 100mm diameter substrate. (right) An image seen in Littrow in the grating grooves.

Figure 12. (left) Front surface interferogram in Littrow at 71.6 ° for a 25 mm beam. The phase peak to valley is 0.146 (λ/6.8) on the front surface at 633 nm, which corresponds to about 2 μm in immersion. Interferometry compares the reflected light from the grating to a near-perfect surface and gives us a measure of how the grating will perform in a spectrograph. It can be correlated to how well the grating grooves are positioned. (right) Front surface monochromatic spectrum of the same grating. A collimated laser beam illuminates the grating in Littrow and that light is reflected back to a camera. Several hundred images are stacked so that we get a high dynamic range measurement.

Figure 13. Efficiency measurements for the IGRINS grating in immersion. The on-blaze efficiency is about 75% across the H and K bands. To measure efficiency we scan the grating, in immersion, over the operating wavelength band and compare the intensity of the incoming light to the reflected light.

Publications

Manufacturing silicon immersion gratings for GMTNIRS on 150-mm material

Benjamin T. Kidder, Cynthia B. Brooks, Michelle M. Grigas, Daniel T. Jaffe

Part of SPIE Astronomical Telescopes + Instrumentation

Process and metrology developments in the production of immersion gratings

Cynthia B. Brooks, Benjamin T. Kidder, Michelle M. Grigas, Sierra Hickman, Daniel T. Jaffe

Part of SPIE Astronomical Telescopes + Instrumentation

A Grism Design Review and the As-Built Performance of the Silicon Grisms for JWST-NIRCam

Casey P. Deen, Michael Gully-Santiago, Weisong Wang, Jasmina Pozderac, Douglas J. Mar, and Daniel T. Jaffe

Publications of the Astronomical Society of the Pacific, Volume 129, Number 976 [web]

Approaching perfection in the manufacturing of silicon immersion gratings

Benjamin T. Kidder, Cynthia B. Brooks, Michelle M. Grigas, Daniel T. Jaffe, Proc. SPIE 9912, Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation II, 99123L (22 July 2016). [web]

New metrology techniques improve the production of silicon diffractive optics

Cynthia B. Brooks, Michael Gully-Santiago, Michelle Grigas, Daniel T. Jaffe, Proc. SPIE 9151, Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation, 91511G (28 July 2014); doi: 10.1117/12.2057468. [web]

Near-infrared metrology of high-performance silicon immersion gratings

Gully-Santiago, M., Wang, W., Deen, C., Modern Technologies in Space and Ground-Based Telescopes and Instrumentation II, Edited by Ramon Navarro, Colin Cunningham, and Eric Prieto, Proc. SPIE, 8450, E2SG (2012). [ web ]

iSHELL: a 1-5 micron cross-dispersed R=70,000 immersion grating spectrograph for IRTF

Rayner, J., Bond, T., Bonnet, M., Jaffe, D., Muller, G., and Tokunaga, A. , Ground Based and Airborne Instrumentation for Astronomy IV, Edited by Ian McLean, Suzanne Ramsay, and Hideki Takami, Proc. SPIE 8446, E2CR (2012). [ web ]

High-performance silicon grisms for 1.2-8.0 micron: detailed results from the JWST-NIRCam devices

Gully-Santiago, M.; Wang, W.; Deen, C.; Kelly, D.; Greene, T.P.; Bacon, J.; Jaffe, D.T.; Modern Technologies in Space- and Ground-based Telescopes and Instrumentation. Edited by Atad-Ettedgui, Eli; Lemke, Dietrich. Proceedings of the SPIE, Volume 7739, pp. 77393S-7 (2010). [ web ]

Manufacturing of silicon immersion gratings for infrared spectrometers

Wang, Weisong; Gully-Santiago, Michael; Deen, Casey; Mar, Douglas J.; Jaffe, Daniel T. ; Modern Technologies in Space- and Ground-based Telescopes and Instrumentation. Edited by Atad-Ettedgui, Eli; Lemke, Dietrich. Proceedings of the SPIE, Volume 7739, pp. 77394L-9 (2010) [ web ]

GMTNIRS (Giant Magellan Telescope near-infrared spectrograph): design concept

Lee, Sungho; Yuk, In-Soo; Lee, Hanshin; Wang, Weisong; Park, Chan; Park,Kwi-Jong; Chun, Moo-Young; Pak, Soojong; Strubhar, Joseph; Deen, Casey; Gully-Santiago, Michael; Rand, Jared; Seo, Haingja; Kwon, Jungmi; Oh, Heeyoung; Barnes, Stuart; Lacy, John; Goertz, John; Park, Won-Kee; Pyo, Tae-Soo; Jaffe, Daniel T.; Ground-based and Airborne Instrumentation for Astronomy III. Edited by McLean, Ian S.; Ramsay, Suzanne K.; Takami, Hideki. Proceedings of the SPIE, Volume 7735, pp. 77352K-9 (2010). [ web ]

Preliminary design of IGRINS (Immersion GRating INfrared Spectrograph)

Yuk, In-Soo; Jaffe, Daniel T.; Barnes, Stuart; Chun, Moo-Young; Park, Chan; Lee, Sungho; Lee, Hanshin; Wang, Weisong; Park, Kwi-Jong; Pak, Soojong; Strubhar, Joseph; Deen, Casey; Oh, Heeyoung; Seo, Haingja; Pyo, Tae-Soo; Park, Won-Kee; Lacy, John; Goertz, John; Rand, Jared; Gully-Santiago, Michael ; Ground-based and Airborne Instrumentation for Astronomy III. Edited by McLean, Ian S.; Ramsay, Suzanne K.; Takami, Hideki. Proceedings of the SPIE, Volume 7735, pp. 77351M-10 (2010). [ web ]

Science instrument development for the Giant Magellan Telescope

Jaffe, D. T.; Depoy, D. L.; Fabricant, D. G.; Hinz, P. M.; Jacoby, G.; Johns, M.; McCarthy, P.; McGregor, P. J.; Shectman, S.; Szentgyorgyi, A. ; Ground-based and Airborne Instrumentation for Astronomy III. Edited by McLean, Ian S.; Ramsay, Suzanne K.; Takami, Hideki. Proceedings of the SPIE, Volume 7735, pp. 773525-8 (2010) [ web ]

A silicon and KRS-5 grism suite for FORCAST on SOFIA

Deen, Casey P.; Keller, Luke; Ennico, Kimberly A.; Jaffe, Daniel T.; Marsh, Jasmina P.; Adams, Joseph D.; Chitrakar, Nirbhik; Greene, Thomas P.; Mar, Douglas J.; Herter, Terry; Ground-based and Airborne Instrumentation for Astronomy II. Edited by McLean, Ian S.; Casali, Mark M. Proceedings of the SPIE, Volume 7014, pp. 70142C-10 (2008). [ web ]

Silicon immersion grating spectrograph design for the NASA Infrared Telescope Facility

Tokunaga, A. T.; Bond, T.; Jaffe, D. T.; Mumma, M. J.; Rayner, J. T.; Tollestrup, E. V.; Warren, D. W.; Ground-based and Airborne Instrumentation for Astronomy II. Edited by McLean, Ian S.; Casali, Mark M. Proceedings of the SPIE, Volume 7014, pp. 70146A-11 (2008). [ web ]

Fabrication and test of silicon grisms for JWST-NIRCam

Jaffe, D. T.; Wang, W.; Marsh, J. P.; Deen, C. P.; Kelly, D.; Greene, T. P. ; Space Telescopes and Instrumentation 2008: Optical, Infrared, and Millimeter. Edited by Oschmann, Jacobus M., Jr.; de Graauw, Mattheus W. M.; MacEwen, Howard A. Proceedings of the SPIE, Volume 7010, pp. 70103L-6 (2008).[ web ]

Micromachined silicon grisms for infrared optics

Douglas J. Mar, Jasmina P. Marsh, Casey P. Deen, Hao Ling, Hosung Choo, and Daniel T. Jaffe; Appl. Opt. 48, 1016-1029 (2009) [ web ]

Production and Evaluation of Silicon Immersion Gratings for Infrared Astronomy

Marsh, J. P.; Mar, D. J.; Jaffe, D. T., Applied Optics, 46, 3400 (2007). [ pdf ]

Performance of large chemically etched silicon grisms for infrared spectroscopy

Mar, D. J.; Marsh, J. P.; Jaffe, D. T.; Keller, L. D.; Ennico, K. A., 2006, Proceedings of the SPIE, 6269, 62695R (2006). [ pdf ]

Fabrication and Performance of Silicon Immersion Gratings for Infrared Spectroscopy

Marsh, Jasmina P.; Mar, Douglas J.; Jaffe, Daniel T., Proceedings of the SPIE, 6269, 62694J (2006). [ pdf ]

GMTNIRS - The High Resolution Near-IR Spectrograph for the Giant Magellan Telescope

Jaffe, D. T.; Mar, D. J.; Warren, D.; Segura, P. R., Proceedings of the SPIE, 6269, 62694I (2006). [ pdf ]

Infrared grisms using anisotropic etching of silicon to produce a highly asymmetric groove profile

Ershov, Oleg A.; Marsh, Jasmina P.; Allers, K. N.; Jaffe, Daniel T., IR Space Telescopes and Instruments. Edited by John C. Mather. Proceedings of the SPIE, Volume 4850, pp. 805-812 (2003). [ pdf ]

Silicon grisms and immersion gratings produced by anisotropic etching: testing and analysis

Marsh, Jasmina P.; Ershov, Oleg A.; Jaffe, Daniel T., IR Space Telescopes and Instruments. Edited by John C. Mather. Proceedings of the SPIE, Volume 4850, pp. 797-804 (2003). [ pdf ]

Production of high-order micromachined silicon echelles on optically flat substrates

Ershov, Oleg A.; Jaffe, Daniel T.; Marsh, Jasmina P.; Keller, Luke D., Proc. SPIE Vol. 4440, p. 301-308, Lithographic and Micromachining Techniques for Optical Component Fabrication, Ernst-Bernhard Kley; Hans-Peter Herzig; Eds. [ pdf ]

Large-area silicon immersion echelle gratings and grisms for IR spectroscopy

Keller, Luke D.; Jaffe, Daniel T.; Ershov, Oleg A.; Marsh, Jasmina P., Proc. SPIE Vol. 4485, p. 385-392, Optical Spectroscopic Techniques, Remote Sensing, and Instrumentation for Atmospheric and Space Research IV, Allen M. Larar; Martin G. Mlynczak; Eds. [ pdf ]

Dan Jaffe, Cindy Brooks, Benjamin Kidder